A lifestyle change works better than a crash diet:

Professionally planned and executed cost optimisation initiatives

can achieve long term profit improvements

and competitive advantage while preserving quality and growth

___________________________________________________________________________________________

Our Optimised Cost Reduction workshops will show you the professional tools and techniques to help you achieve sustainable results

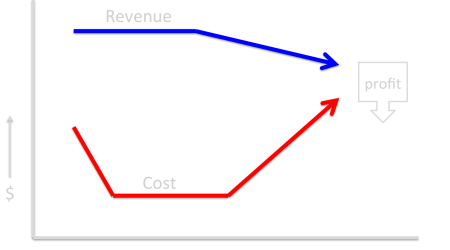

‘Crash diet’ cost cutting vs a structured approach

Cost cutting can become high risk exercises when they are not managed by experts, and may cause adverse impacts on revenue, customer satisfaction and staff morale.

Effective cost reduction is not a financial exercise because costs are not root causes.

Excess costs are the result of value destroying activities in the business.

Our cost optimisation training can help you achieve competitive advantage through a structured enterprise-wide approach which focuses on changing the activities that drive costs, to yield better and more permanent results.

By identifying and addressing the value destroying activities throughout the business and understanding their interdependencies, you can bring costs back into line quickly and permanently without compromising strategic objectives.

Cost optimisation training for executives

Cost cutting is often a knee-jerk reaction to declining profitability and can become a blunt instrument, used by managers-under-pressure who may have little knowledge of the subject.

We tailor in-house Cost Optimisation training workshops specific to your business’ needs to help you reduce costs in a sustainable manner by showing you how to identify and eliminate the root causes of rising costs.

During the training, you will be shown the insider tools and methodologies used by cost reduction specialists including the big four consulting firms, and how to successfully apply these in your business to sustainably increase profitability.

What is cost optimisation

Traditional cost cutting often involves budget driven, arbitrary expenditure reductions which may compromise product and service quality as well as long term profitability.

Cost Optimisation uses a suite of specialist tools and techniques which enable you to examine all business activities which directly and indirectly drive costs.

Using a structured process, non value added activities can be identified and eliminated resulting in a lower cost base.

Integrating the resulting changes into day-to-day management procedures can sustain the benefits while preserving product quality and business growth.

Optimised Cost Reduction workshops

in house executive training, structured to your requirements

During the workshop you will learn how to structure and sustain an effective enterprise wide cost optimisation program including:

How to avoid the most common mistakes made in traditional cost cutting

How to quickly diagnose structural and systemic issues, to create a comprehensive list of enterprise wide savings opportunities

How to eliminate the root causes of excess expenditure, instead of just addressing the symptoms

Aligning change initiatives to strategy, to co-ordinate actions and avoid conflicting initiatives

How to sustain benefits once savings have been achieved

Examples of improvements through use of cost optimisation tools and techniques include:

Operational and Process changes – A food processor increased throughput by 25% without capex

Structural changes – An infrastructure engineering business reduced management layers from 8 to 6

Controllable expenditure – A mining business reduced procurement cost by $10 million p.a.

Improved communication and cross functional collaboration – An agribusiness reduced factory changeovers by 20% through better planning in conjunction with sales and commercial functions